The end client desires to upgrade the

sales reporting for its resources from the current MS Excel spreadsheets to an

online system.

The requirements of the end client were

as follows:

1 .) Consolidate

the data from multiple spreadsheets for

analysis over period in time.

2.) Provide

visibility for sales and expenses by route and truck .

Step 1: the ETL team mapped the spreadsheets onto a database(initially MS

Access) for easy data entry at the client main location for after trip and

before trip details. Attached are the details for the same (appendix a)

Design

of the audit report:

As a first step the ETL team replicated

the audit report for the end client in Powerbi. The purpose of replicating the

audit report was as follows:

1.) Check

whether the numbers are correct as per the data entry done for the end client

2.) Consolidate

all the audit numbers for the end client in one interactive framework.

The details of the replication of the

audit report are in appendix b.

Development of analytics and dashboards:

the ETL team identified four(4) key kpis

for analytic purposes.

·

Sales: date, truck and

route

·

Returned sales-returned

crates, returned full bottles, returned empty bottles: date, truck and route

·

Samples: date, truck

and route

·

Expenses: date, truck,

route and expense type.

The behavior of expense is as follows:

·

Aggregate by date

dimension and expense type

·

Semi aggregate by route

and truck master

·

Non aggregate by item

dimension

The behavior of sales is as follows:

·

Aggregate by date

dimension

·

Aggregate by truck and

route master

·

Non aggregate by

expense type

·

Aggregate by item

entities.

In case of expenses analysis the

analytics to be developed were to be grouped by expense type(that does not fall

in direct hierarchy with route and truck hierarchies). Hence the calculated

measures need to be fixed at each level of analysis by expense type( for route

truck and overall analysis).

Accordingly the etl team developed the

following kpis for the expense analytics:

Expense(fixed overall):

All expense: CALCULATE(SUM(after_trip_allocation[expense]),ALL(after_trip_allocation),after_trip_allocation[type_of_expense_id]>0)

NOTE: The type of expense id was

stipulated to be more than 0 since without the expense id expense aggregate

would not make sense.

Expense across route id and expense nature:the given measures

fixes the total expense

EXPENSE_ACROSS_ROUTE_EXPENSETYPE

= CALCULATE(SUM(after_trip_allocation[expense]),ALLEXCEPT(after_trip_allocation,after_trip_allocation[route_id],'type

of expense'[expense_nature]), after_trip_allocation[type_of_expense_id]>0)

Percentage calculation

for route:

PERCENT_ROUTE =

(after_trip_allocation[EXPENSE_ACROSS_ROUTE_EXPENSETYPE]/after_trip_allocation[expense_excl_nature])*100

Expense across truck id

and expense nature:

EXPENSE_ACROSS_TRUCK_EXPENSE_NATURE

= CALCULATE(SUM(after_trip_allocation[expense]),ALLEXCEPT(after_trip_allocation,Truck_master[Truck_ID],'type

of expense'[expense_nature]),after_trip_allocation[type_of_expense_id]>0)

Percent expense along

the truck route is defined as follows:

PERCENT_TRUCK = (after_trip_allocation[EXPENSE_ACROSS_TRUCK_EXPENSE_NATURE]/after_trip_allocation[expense_excl_nature])*100

Attached is the dashboard for the expense analysis:

Calculation of sold bottles:

Sold bottles is the

difference of quantity loaded,return bottles and sample bottles.

Attached is the snapshot

for the sold bottles

sold_bottles =

SUM('Before_trip_allocation'[quantity_loaded]) -

SUM('after_trip_allocation_item'[Returned_bottles])-CALCULATE(sum(after_trip_allocation_item[returned_full_bottles]),after_trip_allocation_item[sample_flag]="'sample'")

Sold bottles are

calculated on the basis of:

·

Vehicle no.

·

Route description

·

Date dimension

·

Item dimension(brand,volume and holding type)

Attached is the

dashboard of the sold bottles:

Vehicle no and the route

description is the slicer .we can

analyzed the sold bottles for the particular

vehicle and route.

Calculation of sample bottles

Sample bottles is

extracted from the sample flag.

Attached is the snapshot

for the sold bottles

Sample =

CALCULATE(sum(after_trip_allocation_item[returned_full_bottles]),after_trip_allocation_item[sample_flag]="'sample'")

Sample bottles are

calculated on the basis of:

·

Vehicle no.

·

Route description

·

Date dimension

·

Item dimension(brand,volume and holding type)

Attached is the

dashboard of the sample bottles:

Calculation of return bottles:

Return bottles is

extracted from the sample flag.

Attached is the snapshot

for the sold bottles

Returned_bottles = CALCULATE(sum(after_trip_allocation_item[returned_full_bottles]),after_trip_allocation_item[sample_flag]="'returned'")

Return bottles are

calculated on the basis of:

·

Vehicle no.

·

Route description

·

Date dimension

·

Item dimension(brand,volume and holding type)

Attached is the

dashboard of the return bottles:

Appendix

A

LIQUOR

COMPANY MOBILITY APP

The given implementation has been done

to automate the field sales collection data for Liquor Company.

As a first step, the ETL team has

deployed the MS Access database on the client end for data capture of before

and after truck load. That is the ETL team has devised a system wherein it

captures the data when the truck is loaded by various SKUs. Also the end client

inputs the data after the truck has completed its journey.

The benefit to the end client is that

the ms excel spreadsheets shall be replaced by database and consolidated

reporting shall be available to the end client.

Access

Implementation

The end client desired to have a set of reports using PowerBI and database is created in MS Access using the following features:

·

Calculate the crates

loaded on the basis of driver name,areaname,sales person.

·

Calculate the Daily

routine sales and commission report on the basis of brand ,volume and

holding types.

·

Calculate the total

bottles sold after the trip.

Database model for Access interface is

as follows:( the data model was developed by reverse engineering the client

spreadsheets)

Attached is the explanation of the

database model:

Truck Master: The truck master entails all the master data for the

truck.It includes the vehicle no.,driver no.,helper,sales person of the truck.

Route Master: The route master entails all the

master data for the route.The route master

has one to many relation with the truck

master.That is a truck can use the various route to travel or will have

the same route on multiple dates. .It includes all the information of route

i.e. when the journey started ,what was

the meter reading and how many crates

are loaded.

Before trip allocation:

Before trip allocation entails all the information of the item before the

journey was started i.e. how much quantity was loaded of which brand,volume and

holding type.which type of load was it,either it is for “sales” ,”promotion”or

”sample”.

After trip

allocation:it entails all the information of after trip of the truck on the

given route.i.e how any full bottles,emptybottles,emptycrates,breakage bottles

are returned,how much fuel was consumed and the expense details .

After trip allocation

item: it entails all the information of after trip.i.e how any full

bottles,emptybottles,emptycrates,breakage bottles are returned,which types of

material was sold “sample”,”promotion”

or “sold”.

The database is created

in MS Access.There are two buttons before trip and after trip.

Attached is the

snapshot :

Before trip allocation

contains all the details of the truck ,when the journey was started and how

much quantity was loaded of which brand ,what is the volume and the holding

types.

After trip

allocation:the after trip form contain the

after trip allocation detail and expense detail on the basis of vehicle

no. and area name.

Attached is the

snapshot:

After trip allocation

form contains the duration of journey and the description of the sample flag

i.e either the item returned was

“return” or “sample” on the basis of brand, volume and holding types.

Expense detail: This form contains

the expense details of the truck.

Appendix B

Attached

is the explanation for the dashboard developed for replicating the audit

report.

The above portion has been mapped in PowerBI as

follows

Area name and Vehicle no:

These 2 have been assumed to be filter parameter as follows:

Vehicle no. and area

name have been used as slicers for the given

dashboards.

DAX

function:The sample and returned bottles are

calculate by using the dax

functionality.

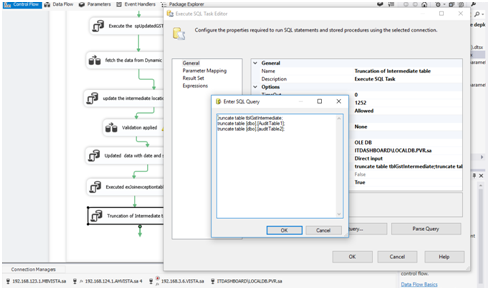

Attached is the

snapshot:

This is the aggregate

function.we use the DAX functionality for the calculation of the returned

bottles

For

the same the etl team generated an aggregate for ‘after_trip_allocation’

Attached

is the snapshot

Cross filter sample:

In case interested in converting spreadsheets to data model, please contact the following:

Name: Apoorv Chaturvedi

Phone: +91-8802466356

email: apoorv@mnnbi.com

Blog prepared by:

Pinky Singh: https://www.linkedin.com/in/pinky-singh-a77a4a180/